Electronics are an essential part of many products designed these days. By their very nature, they are an extremely powerful tool, yet undervalued in the grand scheme of things. There are many reasons why you may need to have a printed circuit board (PCB) designed. You may have a small project where a PCB may help with assembly, or you may be producing 10,000 units of a product you’ve designed and need the electronics to ‘make it all work’. In any case, a PCB can be a big time saver in assembly and manufacturing for any quantity and will increase reliability. PCBs vary widely in complexity. Some are simply a printed wiring board (PWB) and others are full electro-mechanical ‘works of art’.

Printed wiring board (PWB) is an older term used for PCBs. It was exactly what it sounds like, it was a way to print wiring. This term could still be used for very simple PCBs where the function is more for mechanical wiring than active circuitry.

Printed wiring board (PWB) is an older term used for PCBs. It was exactly what it sounds like, it was a way to print wiring. This term could still be used for very simple PCBs where the function is more for mechanical wiring than active circuitry.

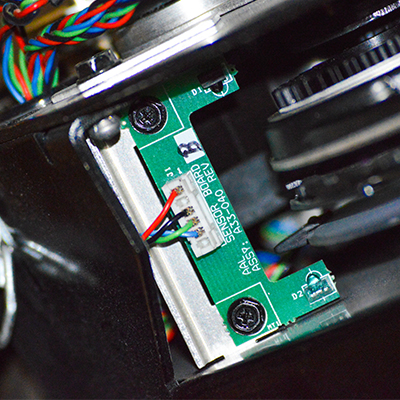

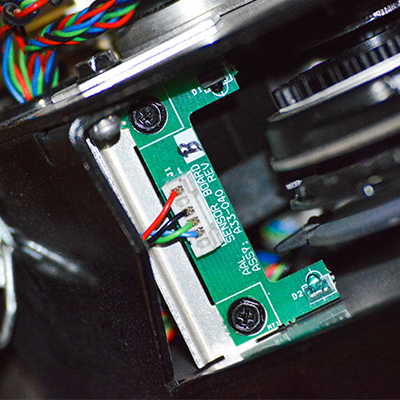

A look inside a modern cell phone is a PCB that reflects the ‘work of art’ side. It’s a finely crafted network of wiring and components, flexible and rigid PCBs which all work together perfectly to provide the functionality we’ve come to take for granted in modern technology.

No matter what your needs are, it’s important to realize that all PCBs are a combination of at least 2, if not more engineering disciplines. Understanding what these disciplines are and how to specify your requirements are important aspects of getting your PCB done right the first time. The disciplines are:

Electrical engineering – this is the obvious one. The goal is to wire electronic circuits together. Of course we’ll need some electrical engineering.

Mechanical engineering – while perhaps not so obvious, we live in the physical world. We are wiring in the physical world so there are mechanical requirements to consider. Some PCBs have very few mechanical requirements like put 4 holes in the corners. Others move towards the work of art level, but most are in between.

Software engineering – Almost all PCBs these days have some level of software in them. If there is a microcontroller, then there is software.

Thermal engineering – Many times grand assumptions are made about the environment something will operate in. The environment something will operate in can change the design drastically. Specialties – If there are lights, then perhaps there is an optical engineer involved.

Other specialties can be involved just depending on what needs to be done.

Below is a How-to guide to help you communicate details of the PCB to your engineer for design of your circuit board

{{cta(‘c11f1602-72cd-4abd-be0b-41cfad610249’)}}

High Level Functionality – The first step is to write down what you want it to do. You can start out with very broad definitions of your inputs and outputs and what it does. Provide whatever level of detail you can. Helpful aspects to think about are parameters like:

|

Think about these types of questions and have an understanding about how it all goes together. Of course your engineer will be happy to fill in the gaps, but the more effectively you can communicate, the better chance of getting what you want and saving costs due to miscommunication.

For more details on how to write a specification, please check out this article.

Mechanical and Thermal Requirements – We know we need to understand the kind of space you want to put your PCB into. Sometimes it’s as simple as ‘put it in this box’. However, even that can lead to issues. What about these questions:

|

Software Requirements – While many boards have very basic functionality like ‘turn this on when this happens’, other PCBs can have very complicated logic built into them. In some cases, software can drive 75% of a PCBs design cost, and sometimes more. Software is a double edge sword in modern day PCB design. On the one hand, it offers extreme flexibility and capability to create complex functionality and control. On the downside, all of the flexibility and control can lead to software never being finished. If there is a new idea to implement, it’s likely you’ll be able to add it in to the software. This is great if it means you can sell more of your product with a software change. It’s not so great if changes are made haphazardly because software changes are ‘easy’. A specification is very important for this phase. Make sure you can answer these questions:

What does the software have to do in all cases? Not just in the main case, but in everything you want it to do.

|

Other Specialties – If other specialty engineering disciplines are required, specification and design can get more complicated. Some companies, like ours, are familiar with LEDs where we can cover most of the requirements for a LED lighting project without an optical engineer. However, there are other cases where complicated instrumentation may need to be researched or subcontracted for very specific design aspects. Below are some examples of some non-standard engineering requirements.

|

- In many of these cases, modules have been developed by 3rd parties that can help reduce the engineering requirements of the specialty work to the level of skilled engineer. In some cases, it is the scientist who needs the PCB built and they can provide the first-hand expertise on how the other engineers need to interface to their specialty systems.

- One more very important engineer that was not mentioned is the manufacturing engineer. This isn’t necessarily a specific engineering discipline, but to consider how your PCB assembly will be produced. Placing a surface mount component is cheaper than placing a through hole component. (Machines do the surface mount work.) There are scores of items to review to ensure high yield PCB development. Many are standard practices, but the skill lies in the hands of the engineers building the board.

- Printed circuit board development is a complex and highly skilled craft. With all of the various skills involved, it is best completed by a team of engineers. Sure, there are many design challenges that are small enough to be completed effectively by a single engineer in a reasonable amount of time. However, as the saying goes, two heads are better than one. Having an engineering team develop your PCB where there are design processes and reviews in place help ensure a high quality design for your product.

{{cta(‘c11f1602-72cd-4abd-be0b-41cfad610249’)}}